SINCR C500 inverter in the power line planes

I. Introduction

The cable industry is currently towards product diversification, the development of production and a higher level of automation technology. In the cable industry, the most widely used is the pay-off, and the power line planes is one in which the high-tech equipment. Power line planes generally require inverter with PID function, and PID control is bidirectional, that is with a reversing control functions. Currently in the industry applications, only a small number of inverter manufacturers can not add any additional accessories can achieve such a request. SINCR C500 inverter is now has this feature domestic inverter, excellent VCC vector control performance and good reliability, but also to ensure superior performance in the cable industry.

II. the process introduced

Power line planes as the front of a variety of equipment, has been widely used in the cable industry. In general, the power line planes have the following requirements:

A, when the speed to take the lead, put the line speed to take the lead followed by rapid acceleration speed;

B, when the speed is reduced to take the lead, put the line speed also followed lead to take to slow down;

C, when run at a steady speed, line planes pendulum to stabilize;

D, when there is tension release, the closing speed also followed the loose line speeds for quick acceleration;

E, when there is disconnection, requires reel stop immediately;

Some of the above requirements completed by the PID function of the inverter, and reflect the requirements of the drive for speed should be very sensitive.

III.the system description

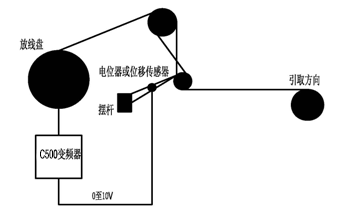

For power line planes requirements of the inverter, the SINCR C500 inverter uses PID control mode, and the PID function enables bidirectional output, so the PID output can easily achieve bidirectional motor reversing control. Inverter frequency control mode open loop vector control process, drive and direction of a given frequency from the frequency converter itself PID given signal source and the feedback signal from the potentiometer or the displacement sensor signal is connected to the pendulum 0 ~ 10VDC conducted PID calculation value, so it can easily achieve the double-acting PID. Deceleration time set to about 1s.

IV.debugging

SINCR C500 in wiring and debugging is very convenient. Commissioning should be noted:

A, before running the selection process control, make sure to carry out auto-tuning operation to automatically identify the drive motor equivalent parameters, such control can drive more accurate and rapid;

B, feedback feature PID action direction selection must be chosen as a positive characteristic;

C, since the power line planes have a brake device, so stop mode select free parking;

D, the SINCR When the drive control is given in units of quantities, the present example is the% of the units, so it is easy to swing lever the maximum position is set to 100% (corresponding to a pendulum potential meter 10VDC), the key is to find debugging pendulum stable point, then this position is defined as the point where the PID given.

C500 parameters are as follows

C500 Parameters setting |

F0.00 | 2 | F9.01 | 50 |

F0.01 | 1 | F9.02 | 0 |

F0.02 | 6 | F9.03 | 0 |

F0.03 |

| F9.04 | 0.3 |

F9.00 | 0 | F9.05 | 5.0 |

V. the advantages of the system

In practice, in response to the SINCR C500 inverter to reflect the speed PID is very sensitive, very good response in both the fast-track speed lines and reverse loose closing line, fully meet customer demand.