Sanding machine is one of the widely used equipments in the modern wood processing industry. It is used for the finishing of various wood-based panels and wood products. The sanding machine is a kind of rear-end equipment for woodworking machinery, usually used by floor manufacturers. The manufacturer determines the amount of sanding according to the thickness of the plate and the production requirements. The sander runs normally with the man-machine interface and PLC control. The man-machine interface is planned for the user to set the complex process such as the amount of sanding required. The types of sanding machines are usually divided into: heavy sanding machine, primer sanding machine, overhead sanding machine, profiled sanding machine, disc sanding machine, pusher sanding machine, etc.

It uses sanding belt and abrasive cloth (paper) to sand the surface of the wood workpiece, which is suitable for sanding of the opposite sex lines, reducing manpower and increasing productivity. Applicable to the profiled or heterosexual line sanding machine. According to the different installation positions of the sand frame and the sand head, the sanding machine can sand the three faces at the same time. The number of sand frames and sand heads can be as required. The increase or decrease can be controlled by the PLC program to be valid/invalid. Primer sanding machine sanding machine equipment generally uses multiple frequency converters (4 ~ 8 sets), control belts, grinding wheels and conveyor belts, through stepless speed regulation, can meet various material requirements, easy to operate. The sander equipment will start the air valve to automatically compensate the contour wheel according to the increase of the machining amount, so as to ensure that the sand head will not change the sanding effect due to the wear of the grinding wheel. Performance requirements for the inverter: The inverter is required to have 2 relay outputs; it has communication function, which can communicate with the touch screen or PLC.

Application of SINCR frequency converter in sanding machine

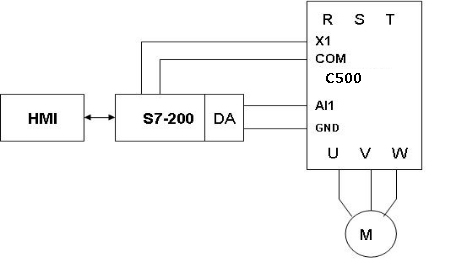

Control principle:

The sander is mainly processed with plywood to meet the thickness and smoothness requirements. The transmission part is mainly composed of the belt motor and the conveying motor. The transmission motor is controlled by the inverter. The system consists of touch screen, PLC and inverter. The transmission speed and start-up are adopted. The commands are all set in the touch screen. The inverter speed control signal is output by the PLC according to the requirements of 0~10V analog signal, thus controlling the speed of the conveyor belt motor.